Production Process

Over 30 Years Of Experience

Fairwind has a factory area of over 30,000 square meters, equipped with professional production machine and office appliance. The company is mainly divided into several function areas for office, metal processing, fabric cutting, sewing, assembly, raw material warehouse and finished product warehouse. At the same time, the company also has sample exhibition room and design room.

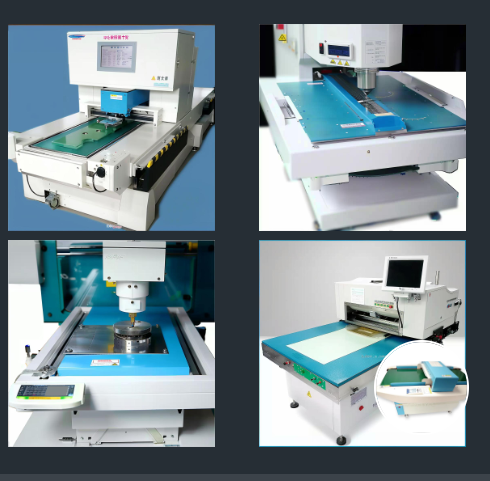

In terms of equipment, the company is equipped with a full set of metal surface treatment and processing line, professional template design software and making machines, fully automatic sewing machine, and four sets of flexible assembly lines. Meet the design and production needs of different types of products.

Wide Product Range To Choose From

Fairwind has a total of 1,000+ employees and an average monthly production capacity of 300,000 pieces of various products. The products it produces cover multiple outdoor product categories: beach chairs, camping chairs, picnic tables, camping strollers, etc. At the same time, we provide OEM and ODM services, and customize unique outdoor tool products according to customer requirements to meet the diverse needs of various markets.

Production Capacity

Professional Manufacturers

As a well-known outdoor camping equipment manufacturer in China, we are committed to providing high-quality camping chairs, beach chairs, wagon, camping tables and other leisure products.

Maximizing Output

We have a full set of metal processing and surface painting equipment, professional automated sewing machines, 50+ sewing workers, and 5 professional assembly lines.

Quality Assurance

Our company's advanced production equipment and strict quality control system ensure that every product is carefully crafted and rigorously tested to ensure its quality and reliability.

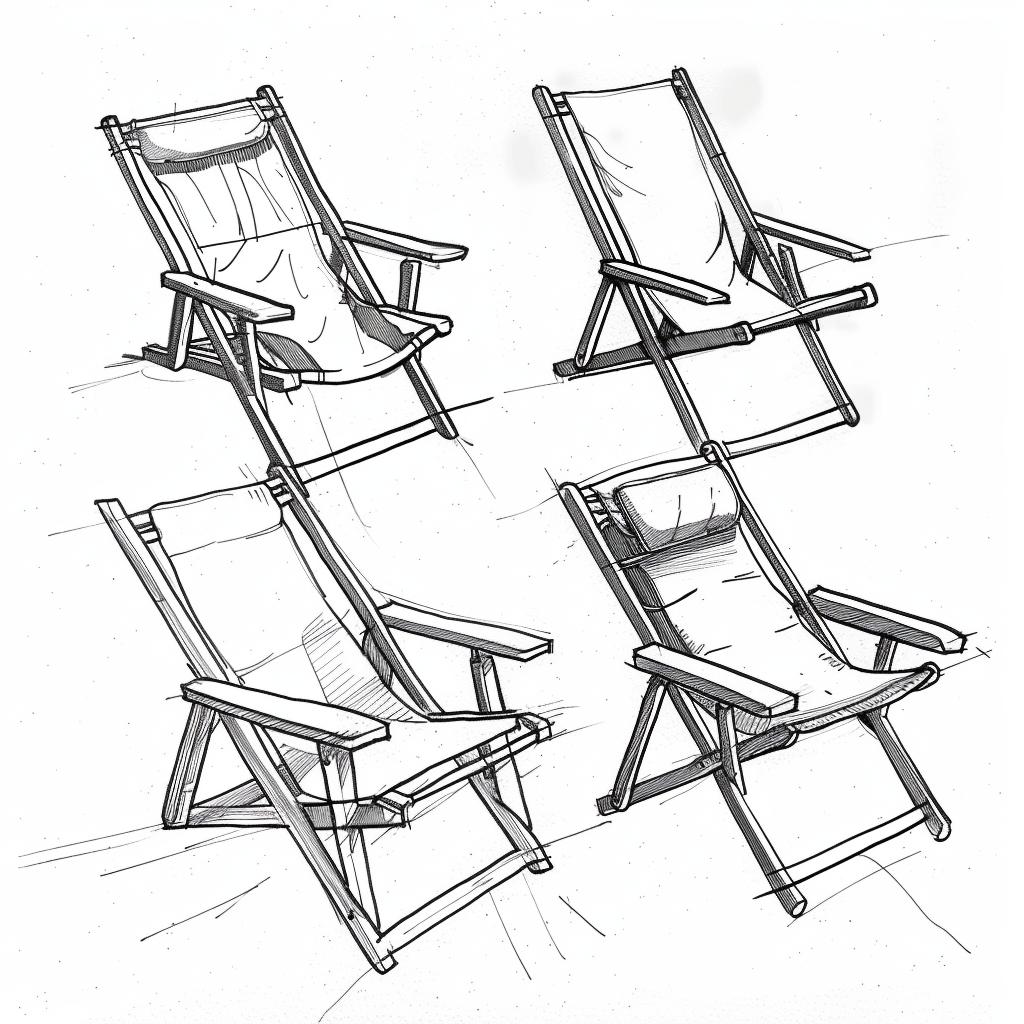

--Design & Manufacturing Process--

》Preparatory Stage

1. Design: Generate product design plans and effect displays through computers and other auxiliary equipment.

2. Pattern making: Make prototypes of various structures such as chair surfaces, pipe fittings, spare parts, etc.

3. Sampling: Generate samples and fine-tune designs and templates until they are finalized.

Design

Pattern Making

Sampling

》Production Stage

1. Metal Processing: Processing operations such as cutting, drilling and bending of metal pipes and parts.

2. Spray Painting: Spray paint on the surface of processed metal pipe fittings and accessories.

3. Fabric Cutting: Cut the fabric according to the sample specifications.

4. Sewing Process: Sew each piece of fabric, accessories, and filling cotton together to form a complete chair surface.

Metal Processing

Spray Painting

Fabric Cutting

Sewing Process

》Completion Stage

1. Assembly: Construct the painted pipe parts into the chair structure and install the seat surface in it.

2. Quality Inspection: Conduct quality inspection on the assembled products to ensure that only products that meet quality standards will enter the packaging process.

3. Overall Packaging: Pack the product into boxes and prepare for shipment.

Assembly

Quality Inspection

Overall Packaging

--Quality Control--

We have always adhered to strict quality control, which covers every aspect of product production from beginning to end.

1. RAW Materials

All purchased raw materials and accessories, including fabrics, metal tubes, plastic parts and other accessories, are quality tested immediately. Through various methods such as random inspection and laboratory testing, we ensure that the performance and quality of each batch of raw materials meet production standards. Raw materials that do not meet the standards will not be accepted and will not be used in product production.

2. In-production testing

Semi-finished products are inspected at every stage of production, and existing problems are solved promptly to ensure that problematic semi-finished products will not flow into the next process.

3. 100% Pre-packaging inspection

Before packaging of finished products, all produced goods will be assembled and tested to ensure that the goods can be used normally. Any products with quality issues will not be packaged and shipped.

4. Sampling Test

The factory is equipped with professional impact, pressure, strength and other testing equipment, and each batch of products produced will be randomly tested.

We ensure the quality level of our products through quality control covering the entire process.

--Why Choose Us--

OEM/ODM Customized Services

We provide all-in-one customization solutions for outdoor products such as camping chairs, tables, and carts. The options include various styles, designs, materials, colors, logos, patterns, packaging, and accessories, etc.

Customer-Focused Design

Every designer and engineer on our team is dedicated to magnifying the smallest details, ensuring that every product leaving our factory is not only thoughtfully designed, but rigorously tested to deliver unparalleled quality and performance.

Exclusive Production Line

Your products are custom-made with tooling and molds. The resources and production of your product remain private and are not shared with third parties. An exclusive production line for such products is operated under your control.

Quick Response

We rely on efficient workflows and flexible project management to ensure timely responses to your needs. Whether it's an urgent design adjustment or a quick production cycle, we aim to exceed expectations and prioritize customer satisfaction.